How a dairy farm increased their milk production 18% with IoT and Machine Learning

According to the SDG Goal 2: Zero Hunger, by 2050, the global population will be 9.8 billion. Getting food production to be as effective as possible is not only an economic challenge, it is also a worldwide urgency.

Although Russia is moving towards dairy Smart Farming by incorporating new techniques, the Internet of Things, machine learning and genetically modified cattle breeding, it is still one of the countries with the highest milk deficits according to FAO.

IoT tools make it possible to know customers better

To help food producers cope with the challenges ahead, the russian company ALAN-IT developed a dairy production management service Dairy Production Analytics (DPA) supported on the cloud-based analytical service Smart4Agro, that offers help livestock decision-making with a forecast accuracy of 92-97%. DPA gives extra information about the environmental conditions to veterinarian teams such as temperature, humidity, pressure, cow health and other parameters.

Mustang is a russian supplier of feed and feed solutions for farms. Utilising a technological approach, their goal is to increase their profit by feeding their clients’ animals more efficiently. Mustang uses DPA for clients to provide better consulting and meet planned targets.

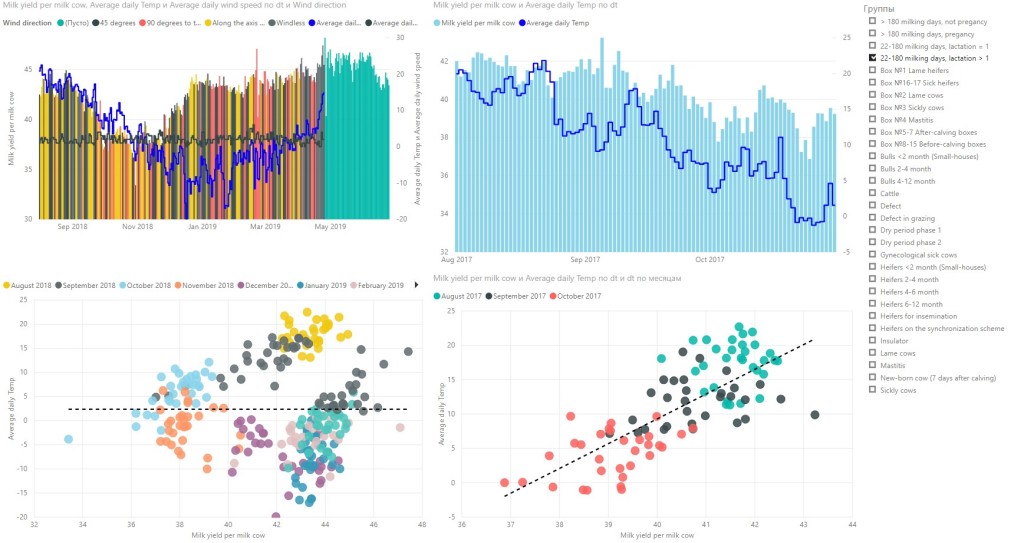

Some graphics of the DPA systems

DPA has been implemented in one of Mustang’s customers, Voshazhnikovo farm. This smart farm has the capacity about 8000 heads of cattle, 4,500 of which are dairy cows. Before the implementation, used to produce 125 tons of milk daily, almost 28 kg per cow and day.

Location of the installation

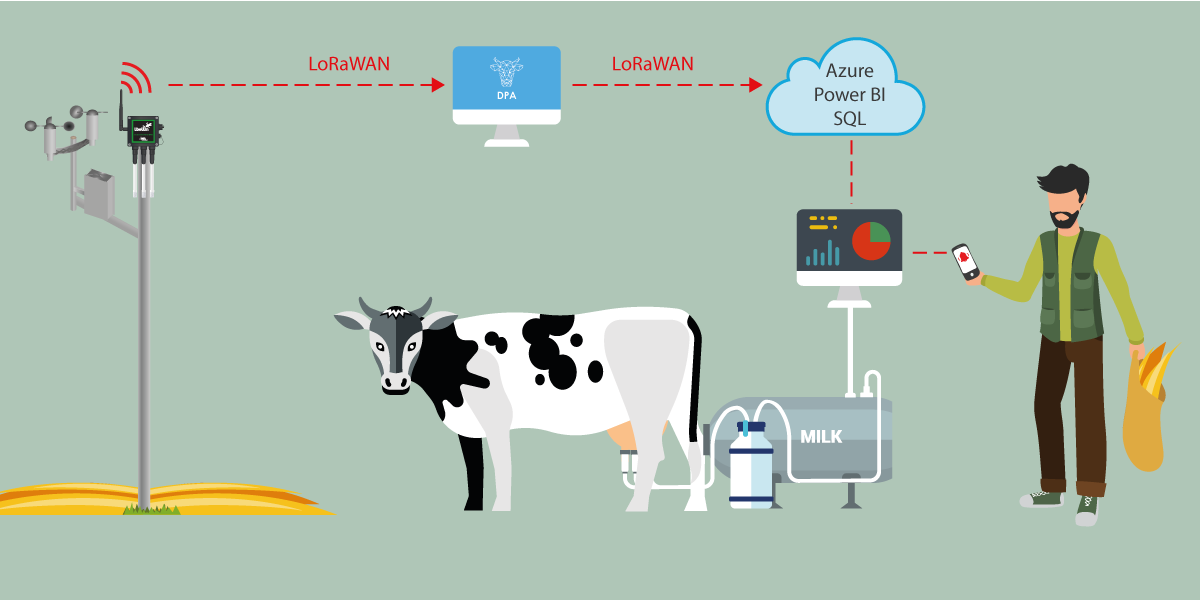

To improve forecasting performance, DPA collects data with external sources: weather station and sensors by Libelium (temperature, pressure, wind speed and direction, precipitation, humidity level, illumination), RFID tags, ERP-system, Excel reports and different external data sources to the cloud-based data platform in the farm. Then some of it goes directly to Power BI and the rest is processed with Azure Machine Learning to help staff make better decisions. The communication protocol between the devices and the gateway and between the gateway, and the cloud is LoRaWAN.

Diagram of an installation

Libelium P&S! Smart Agriculture installation into DPA system

ALAN-IT chose Libelium Plug&Sense! Smart Agriculture, with temperature, humidity and pressure sensor probes and a meteorological station, because according to Alena Shpigareva, Chief Business Development Officer in ALAN Company, they are “ready certified devices on the market that can be quickly purchased and installed.” She added: “we needed to work in a short time with stable devices”so Libelium was their optimal solution.

As a result, the correlation was found between temperature, nutrition, and even daily performance of farmworkers. DPA found out that if temperature decreases in the farm, the cow’s needs for feed increases. The system warns the staff about these changes and farmers receive notifications by mail or SMS. With proper feeding, milk yield rises. As a result, Voshazhnikovo smart farm gets better figures: the savings in the feeding for 2000 dairy cows is €340,000 for 180 days.

P&S! Smart Agriculture installed in the farm to watch the temperature of the cows

P&S! Smart Agriculture installed in the farm to watch the temperature of the cows

This project is designed to predict herd reproduction, milk production and animal diseases based on a combination of external and internal factors, statistical data, economic indicators, staff information and laboratory data. It allows not only to reduce the costs associated with the maintenance of the health of cows, labour and reproduction, but also the strategic tasks of the business: expand production, open new units, etc.

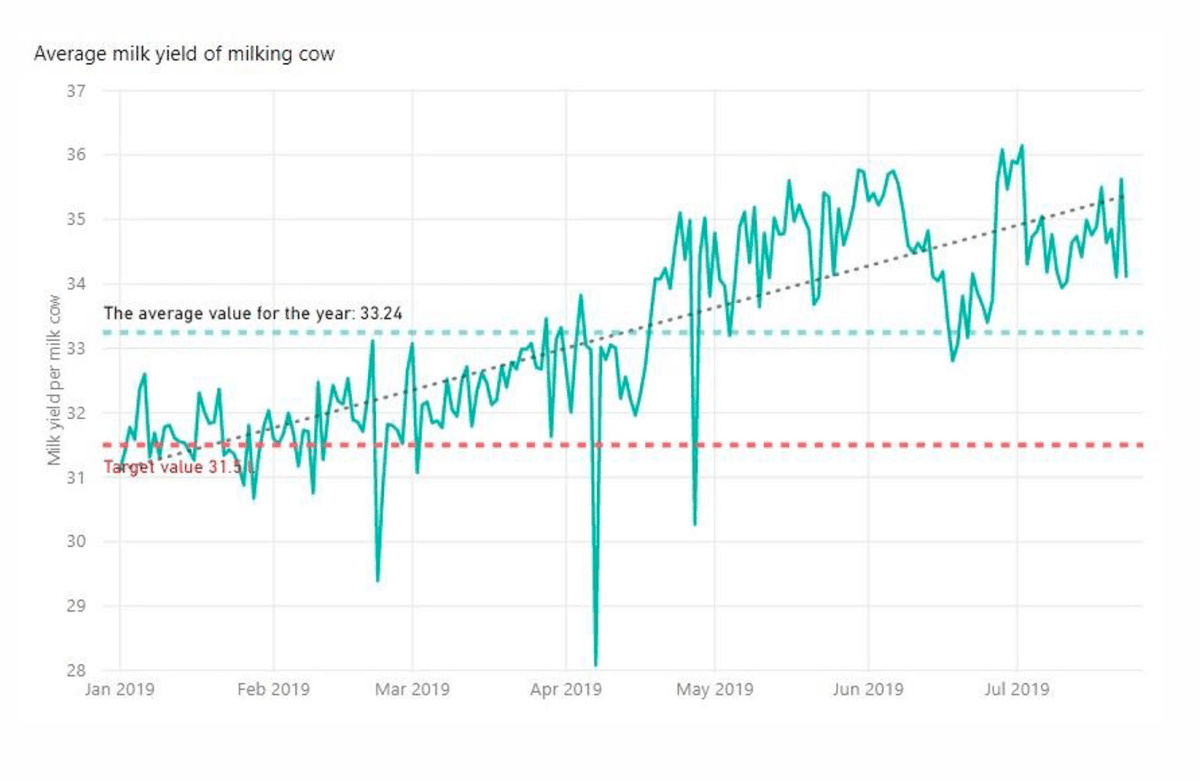

In January, three months after implementing DPA, milk production in Voshazhnikovo Smart Farming increased to 33 kg per cow and day, this is an impressive 18% more than in the previous months (28 kg per cow and day).

Voshazhnikovo farm increased to 33 kg per cow and day; this is 18% more

Haben Sie noch Fragen?

Kontaktieren Sie unsere Experten, um mehr zu erfahren